Ore Dressing Plant High-Precision Belt Scale Case

Case Overview

Before the renovation project, the customer had installed a conventional ICS series belt scale, which lacked high accuracy and required frequent calibration. Now, they have urgently replaced it with a high-precision belt scale. The project deadline is September 3rd, as per the mine's requirement. Upon communication with the customer via phone, a Yuanbang sales engineer promptly flew to the customer site. They conducted on-site measurements, selected the appropriate model according to the customer's requirements, and successfully completed the project on time.

Conveyed Material: Iron Powder

Conveying Flow Rate: 100T/H

Belt Width: 800mm

Conveyor Angle: Horizontal

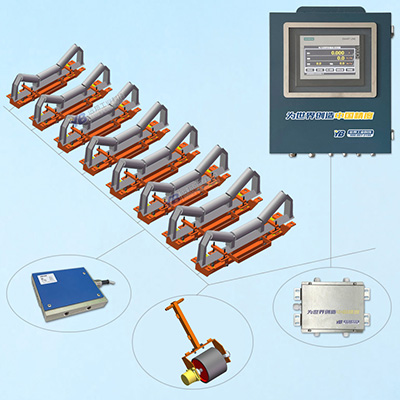

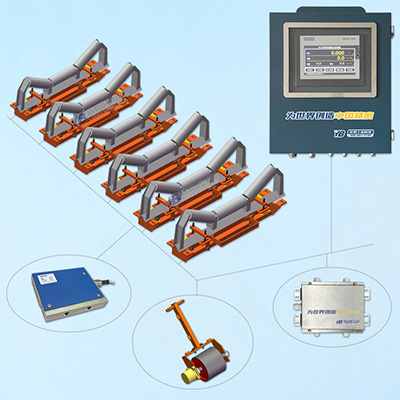

Equipment Configuration: 1 set of YB-GZK-8T High-Precision Belt Scale

Equipment Quantity: 1 set

Equipment Features:

Multiple sets of scale frame combination structure

High-precision automatic hanging code calibration technology

High-precision digital sensors

Regular automatic calibration

Multi-scale intelligent real-time calibration