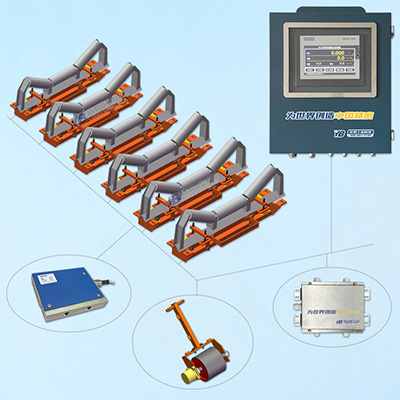

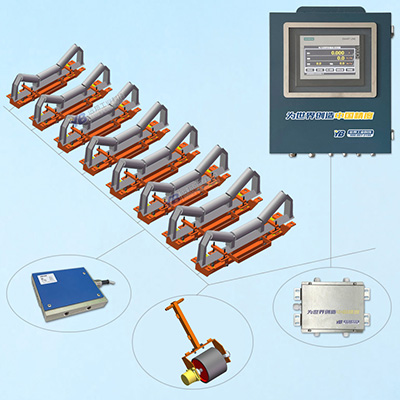

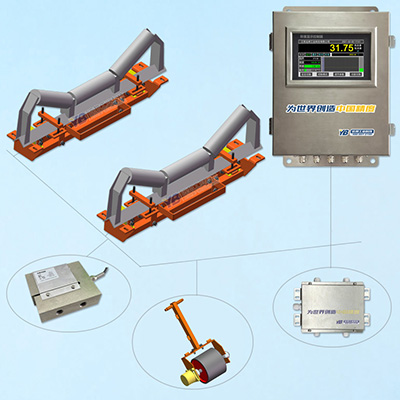

High-precision group control instrument:

Consisting of a 32-bit CPU, built-in high-precision weighing program, touchscreen human-machine interaction system, various digital and analog input/output interfaces, and communication interfaces. Supports simultaneous connection of 24 sets of sensors. Faulty sensors can be automatically removed without affecting overall functionality. Features include automatic zero tracking and temperature compensation.

Full-Suspension Weighing Bridge:

Independent scale body, directly load-bearing scale bridge structure, high-strength scale body, effectively avoiding the influence of deviation; the weighing rollers directly act on the weighing sensors under dynamic load, weight signals are directly transmitted, tare and gross weight are weighed simultaneously, suitable for various materials, providing more accurate measurement. Maintenance-free, heat treatment process, overall spray coating treatment.

12 weighing sensors:

Comprising 12 SPH high-precision dynamic load anti-lateral force sensors, with a parallelogram outer shape and an internal triple-beam structure. Each sensor processes a separate signal entering the acquisition unit for individual data calculation. This effectively counters lateral forces and internal torque between the two sensors, ensuring the maximum reduction of belt misalignment and material loading effects while maintaining dynamic measuring accuracy.

Heavy-Duty Wheel-Mounted Speed Measuring Device:

Featuring a robust wheel-mounted speed measurement structure, integrated with imported core speed measuring components, this device offers high precision speed measurement. Enclosed in a sealed casing, it is waterproof, dustproof, and boasts a long lifespan. The rubber-coated treatment prevents slippage and ensures accurate speed measurement.