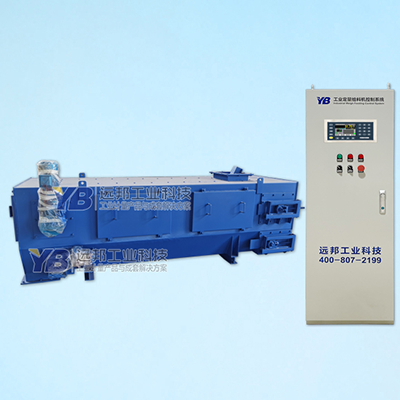

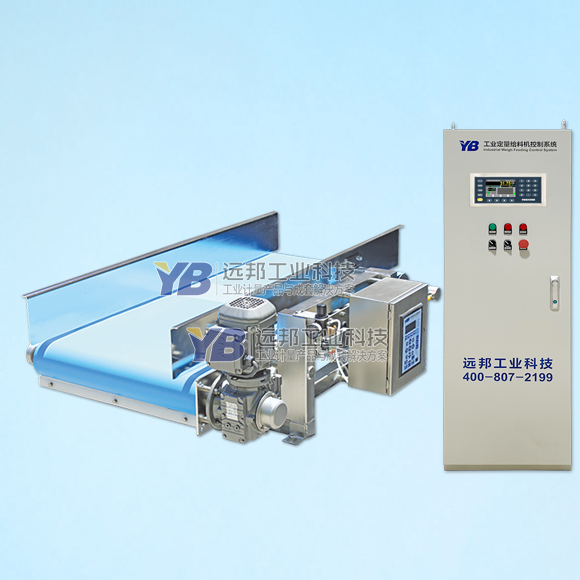

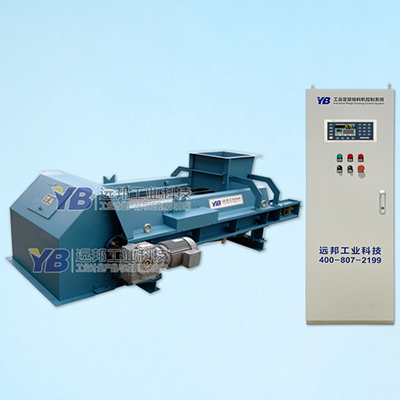

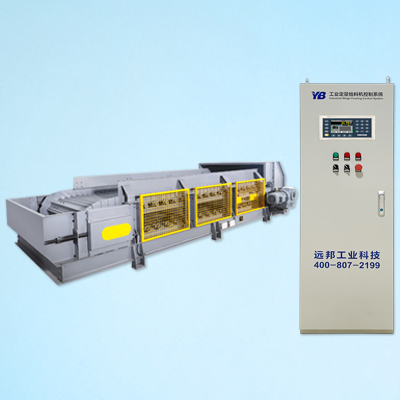

Features:

1. Made of high-quality cold-rolled processed steel, ensuring long-term use without deformation and excellent stability. High precision in processing transmission and sealing components.

2. Embedded weighing bridge structure with simplicity and strong rigidity for more stable measurements.

3. Utilizes high-precision and highly sensitive sensors to effectively resist uneven loads, reduce the impact of belt deviation, and significantly minimize nonlinear errors.

4. The weighing display instrument offers functions like automatic calibration, zero adjustment, interval adjustment, and fault diagnosis, with an optional automatic zero tracking feature.

5. The drive unit employs a directly connected cycloidal pinwheel reducer, resulting in low noise, vibration-free operation. Simple operational maintenance and straightforward calibration

methods.

6. Incorporates advanced system stability in conveying technology, featuring self-alignment, self-cleaning, and self-tensioning system devices. Comprehensive interference-resistant protective measures create the most accurate, stable, and optimal belt quantitative feeder.

7. Patented cleaning system ensures long-term material-free operation, preventing material accumulation and preserving the service life and weighing accuracy unaffected by material deposition.

Composition:

1. Conveying System: Includes conveyor frame, motor gearbox transmission device, conveyor belt, rollers, tensioning device, internal and external cleaning devices, and more.

2. Weighing System: Comprises weighing control instrument, weighing sensors, weighing bridge, speed sensor, and so on.

3. Control System: Encompasses control cabinet, low-voltage electrical circuits, variable frequency drive, and more.