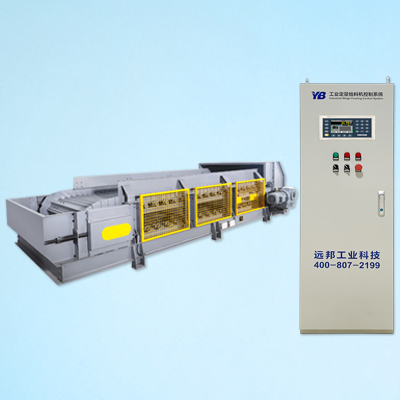

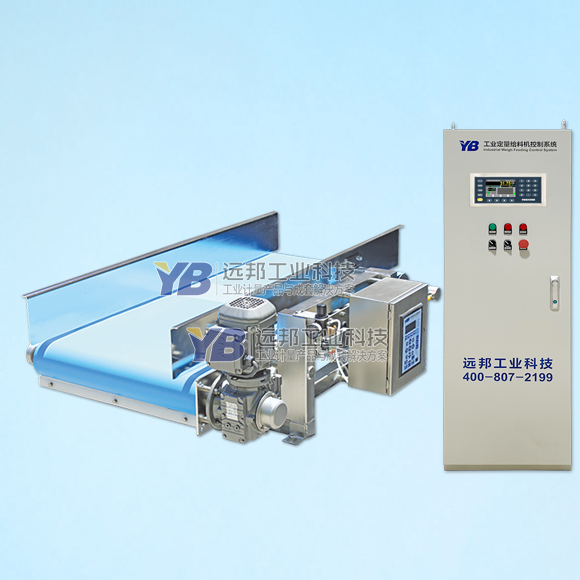

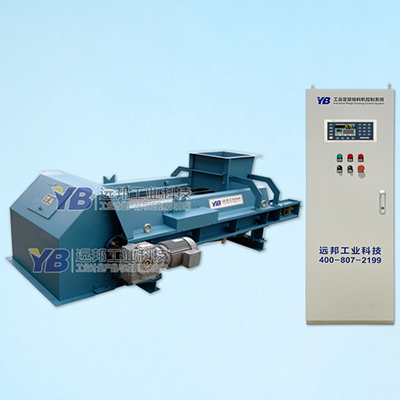

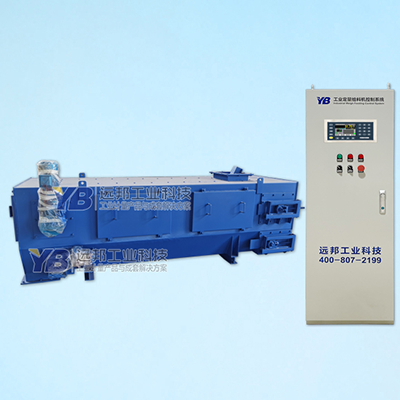

Chain plate quantitative feeder is designed with the concept of "low frequency, heavy load," composed of several wear-resistant metal lining plates with edge baffles linked together, and weighed through two sets of bridge-type weighing modules. The product is specifically developed for high-temperature materials, abrasive materials with angular shapes, and materials with high viscosity and water content. It is an ideal equipment for the batching process of high-temperature clinker, limestone, clay, and gypsum.

The double-chain drag design ensures smooth operation without misalignment. The T-shaped structure of the dual-side rollers results in noise levels below 40 decibels during operation.

Integrated dragging ensures more accurate feeding. It uses a shaft-mounted direct-coupled reduction motor for smooth operation and long service life.

The unique curved chain plate is applied to highly viscous materials, such as clay and gypsum. Precision-manufactured cast steel rollers have a long lifespan and are easy to replace.

It employs intelligent digital instrument control for more comprehensive data collection, smarter control, and more detailed event alarms. The system features various bus communication interfaces, enabling intelligent centralized control.