High Precision Weighing:

Independently developed microchip controller, fully digital weighing technology, industry-proven overall structural design, and dual closed-loop PID regulation achieve higher precision feeding technology, with static accuracy better than 0.1%; linear, repeatability dynamic accuracy better than 0.3%.

Excellent Control Technology:

Controlled by a dedicated microchip for loss-in-weight scales, it offers more advantages compared to ordinary PLCs, with high-speed computation, quick response, stable operation, achieving higher feeding accuracy and stability. It features 2 communication interfaces for data exchange with touch screens, industrial PCs, etc.

High Corrosion Resistance and IP Protection Rating:

All parts in contact with materials are made of 304 stainless steel, with an appearance treated by electrolytic polishing process, combining aesthetics and stability. Even in harsh environments, it is durable and suitable for industries such as pharmaceuticals, food, and chemicals that demand cleanliness and corrosion resistance.

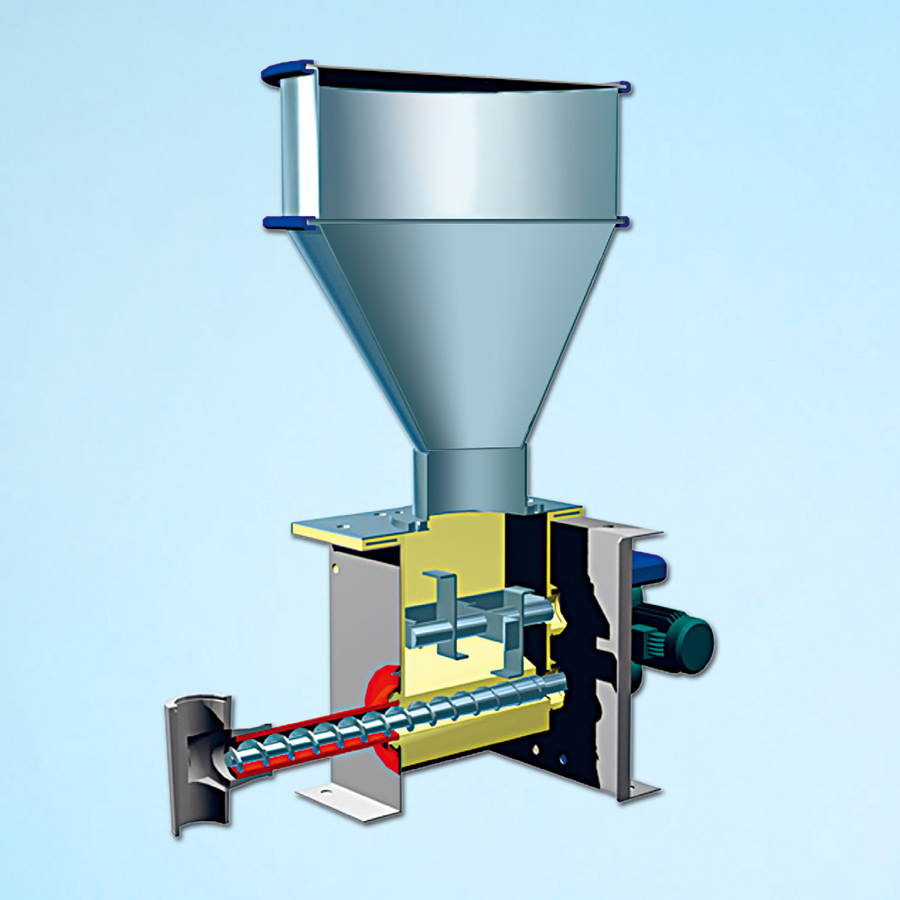

Dual Arch Breaking Mechanism:

Featuring a specially designed spherical hopper structure, for high viscosity, high specific gravity materials, a dual arch breaking mechanism is employed: vertical arch breaking agitator + horizontal mixing device, ensuring smooth discharge of any material while fully ensuring the stability of feeding accuracy.

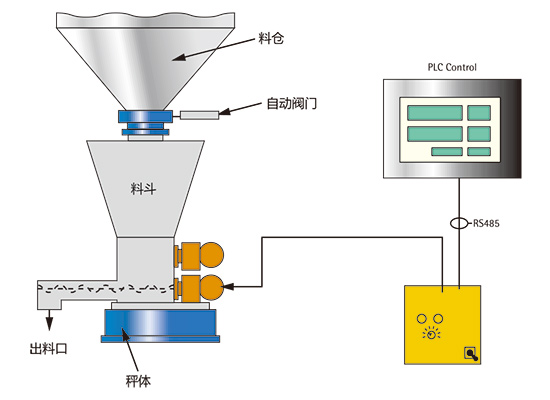

Principle:

The loss-in-weight scale weighs the measuring hopper and the entire feeding mechanism as one unit. As material flows out of the loss-in-weight scale, the control system rapidly and frequently collects weight signals from the scale body, calculates the weight reduction of the material in the measuring hopper per unit time, and determines the actual flow rate of the loss-in-weight scale through unique filtering and optimization processes. Simultaneously, the control system compares this feeding speed with the preset feeding speed, and feeds the comparison result back to the feeding mechanism of the loss-in-weight scale to automatically adjust the feeding speed, forming a closed-loop control, thereby making the actual flow rate infinitely approach the desired flow rate to meet control requirements.

| Mode | Remarks | Flow | Materials | Hopper | Accuracy | mode of operation | communication |

|---|---|---|---|---|---|---|---|

| YB-SZC-S28 | Single Screw | 5~300L/H | Granules、Powder | 40L、60L、100L、150L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-S38 | Single Screw | 15~1500L/H | Granules、Powder | 40L、60L、100L、150L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-D28 | Twin Screw | 2~200L/H | poorly flowing granules and powders | 40L、80L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-D38 | Twin Screw | 15~500L/H | poorly flowing granules and powders | 80L、150L、200L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-D48 | Twin Screw | 50~1500L/H | poorly flowing granules and powders | 100L、150L、250L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-J-D28 | twin-screw with mixing | 10~250L/H | Powder、Glass fibers、Flakes | 60L~120L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-J-D38 | twin-screw with mixing | 30~1200L/H | Powder、Glass fibers、Flakes | 80L~180L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-J-D45 | twin-screw with mixing | 60~100L/H | poorly flowing granules and powders | 40L~100L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-J-D70 | twin-screw with mixing | 80~1200L/H | poorly flowing granules and powders | 100L~200L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |