High Precision Weighing:

Independently developed microchip controller, fully digital weighing technology, industry-proven overall structural design, and dual closed-loop PID regulation achieve higher precision feeding technology, with static accuracy better than 0.1%; linear, repeatability dynamic accuracy better than 0.3%.

High-Precision Feeding:

Based on extensive industry experience and specialized knowledge in batching system design, we utilize independently developed control instruments capable of multi-stage feeding. This allows for high-speed, high-precision batching, achieving optimal control over material drop amounts and timing. The accuracy can reach up to ±0.1g.

Flexible Recipe Management:

The system can store over 1000 recipes and manage them according to user needs, effectively saving production time. It also records and prints the results of each batching, generating and printing daily and monthly reports for easy management and statistical analysis.

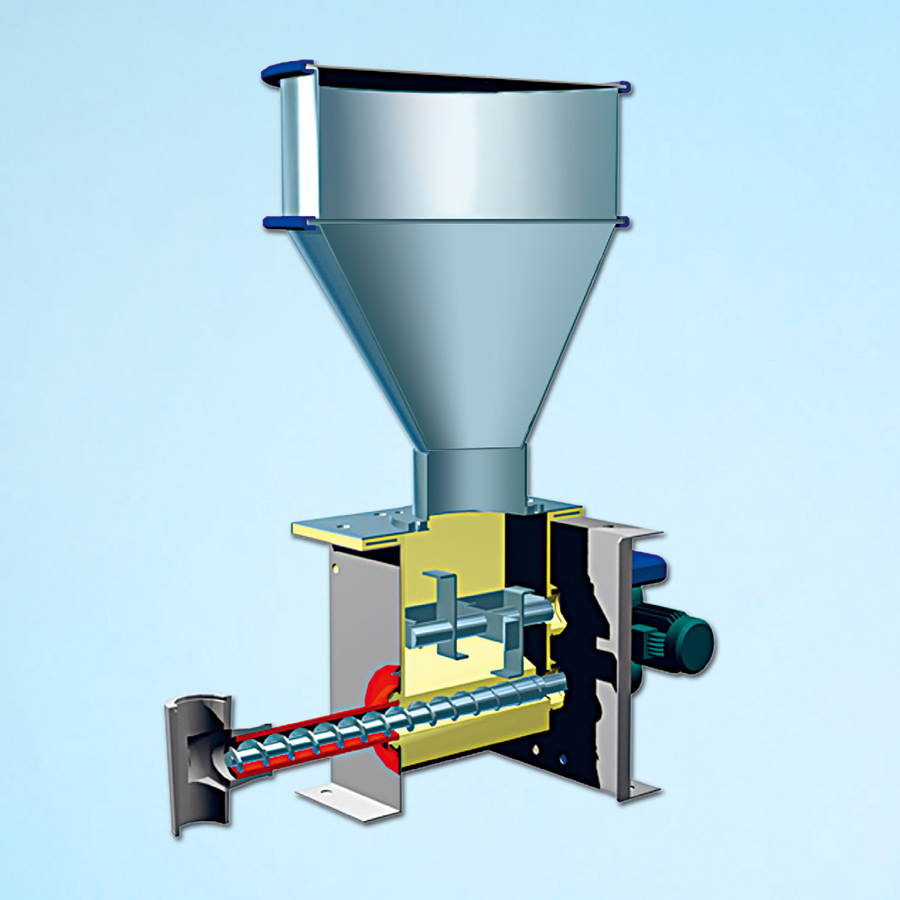

Stainless Steel Hoop Structure: Easy to Maintain:

Unlike traditional welded or flanged joints, Farbond uses a stainless steel hoop structure. This not only improves shock absorption and sound-dampening effects, but also significantly increases the scale body's tensile capacity. Moreover, the main components can be disassembled without tools, making it easy to assemble, disassemble, and clean, thus facilitating maintenance.

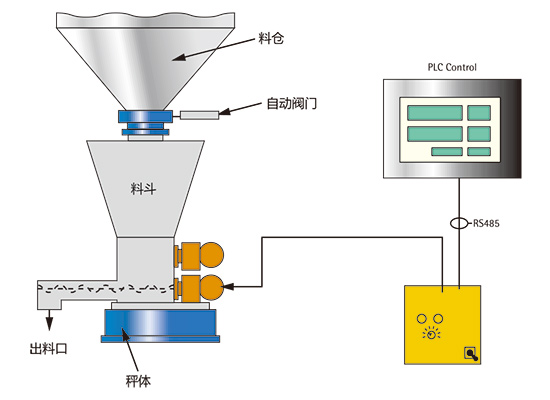

Principle:

The loss-in-weight scale weighs the measuring hopper and the entire feeding mechanism as one unit. As material flows out of the loss-in-weight scale, the control system rapidly and frequently collects weight signals from the scale body, calculates the weight reduction of the material in the measuring hopper per unit time, and determines the actual flow rate of the loss-in-weight scale through unique filtering and optimization processes. Simultaneously, the control system compares this feeding speed with the preset feeding speed, and feeds the comparison result back to the feeding mechanism of the loss-in-weight scale to automatically adjust the feeding speed, forming a closed-loop control, thereby making the actual flow rate infinitely approach the desired flow rate to meet control requirements.

| Mode | Remarks | Flow | Materials | Hopper | Accuracy | mode of operation | communication |

|---|---|---|---|---|---|---|---|

| YB-SZC-S28 | Single Screw | 5~300L/H | Granules、Powder | 40L、60L、100L、150L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-S38 | Single Screw | 15~1500L/H | Granules、Powder | 40L、60L、100L、150L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-D28 | Twin Screw | 2~200L/H | poorly flowing granules and powders | 40L、80L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-D38 | Twin Screw | 15~500L/H | poorly flowing granules and powders | 80L、150L、200L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-D48 | Twin Screw | 50~1500L/H | poorly flowing granules and powders | 100L、150L、250L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-J-D28 | twin-screw with mixing | 10~250L/H | Powder、Glass fibers、Flakes | 60L~120L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-J-D38 | twin-screw with mixing | 30~1200L/H | Powder、Glass fibers、Flakes | 80L~180L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-J-D45 | twin-screw with mixing | 60~100L/H | poorly flowing granules and powders | 40L~100L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |

| YB-SZC-J-D70 | twin-screw with mixing | 80~1200L/H | poorly flowing granules and powders | 100L~200L | ±0.2% | Continuous or Batch | RS-232/RS-485/Profinet |