Coking Plant High-Precision Intelligent Control Belt Scale Case

The Jiangsu Yuanbang YB-GZK high-precision intelligent control belt scale is applied to a coking coal production line at the customer's facility. In this production line, coke produced from boilers is conveyed via a conveyor belt to storage silos, where the next step is loading the coke onto trucks. The Jiangsu Yuanbang high-precision intelligent control belt scale is installed on this conveyor belt to accurately measure the production output of the refined coke, fulfilling its role in precise production yield monitoring.

Location: Pingdingshan, Henan

Material to be Weighed: Coke

Conveyor Belt Width: 1.4 meters

Conveyor Slope: Horizontal

Equipment Purpose: To measure the amount of coke conveyed to the storage silo

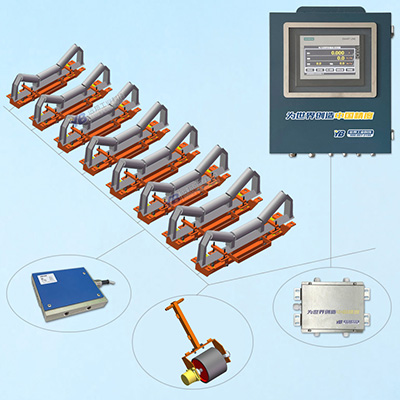

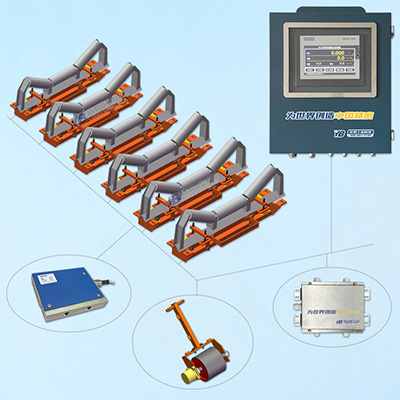

Equipment Configuration: YB-GZK High-Precision Intelligent Control Belt Scale

Equipment Quantity: 1 set

Due to busy production schedules, the customer's onsite belt conveyor cannot be stopped for extended periods. It operates in an intermittent manner, running for about 30 minutes and stopping for about 15 minutes. This intermittent operation poses time and operational challenges for installing our high-precision intelligent control belt scale. To avoid interrupting the customer's production, sales engineers from Jiangsu Yuanbang Industrial Technology worked overtime, seizing every moment during the conveyor's downtime. After nearly 10 consecutive days of intensive work, the installation of the belt scale was successfully completed.

Through this project collaboration, the high-precision intelligent control belt scale was installed and commissioned without disrupting the customer's ongoing production. This earned the trust and praise of the customer. Jiangsu Yuanbang Industrial Technology also gained valuable project execution and operational experience, promising smoother cooperation in future endeavors.