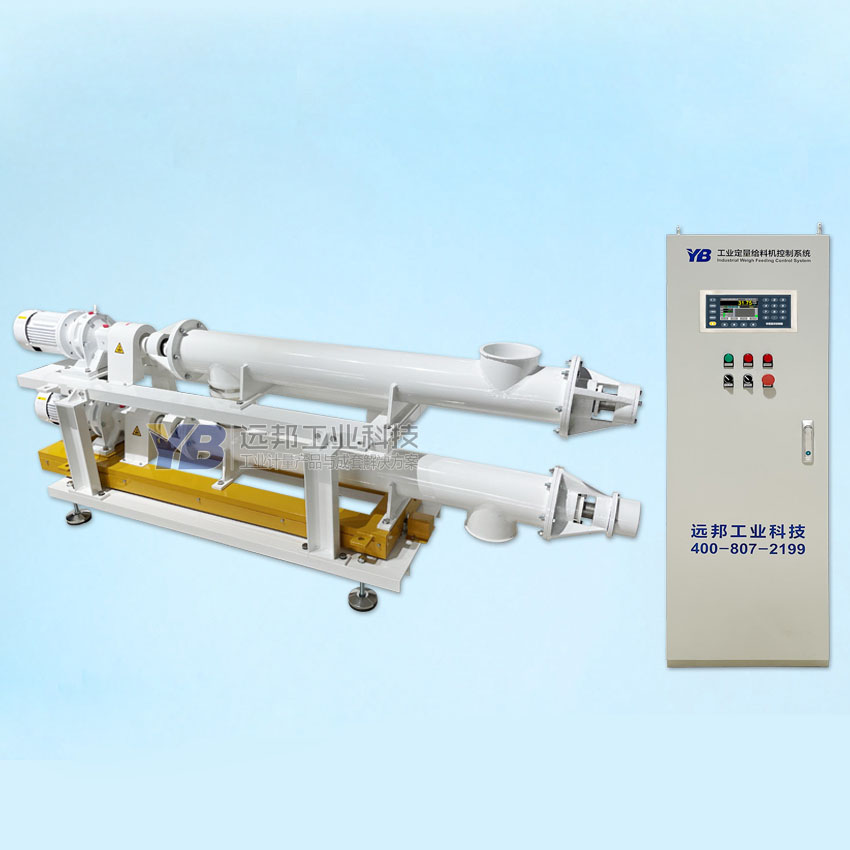

Precision Mechanical Manufacturing Process:

It employs higher-precision mechanical machining equipment and fully automated precise welding techniques to create high-quality seamless steel pipes. This results in excellent overall rigidity and strength, ensuring better accuracy in dynamic balance control.

Specially Designed Inlet and Outlet for Smooth Material Feeding:

The steady-flow spiral utilizes variable pitch structure and overflow outlet design, effectively addressing material clogging issues. Variable diameter, variable pitch, and overflow outlet ensure even material settling, stable control, no bin collapse, no dusting, and no material surging.

Self-Developed Touchscreen Intelligent Control Instrument:

Designed specifically for spiral batching systems, this intelligent control instrument features EMC design for strong anti-interference capabilities, particularly suitable for industrial batching environments. Unique anti-vibration filtering algorithms, high-frequency sampling, precise weighing, stable display, fast response, meeting high-precision and production reliability requirements.

High-Precision Digital Weighing Module:

It allows the selection of 1 or 3 high-precision weighing sensors based on on-site conditions. Using digital transmission technology, it offers a simple circuit, no adjustment components, high resolution, signal integrity, and strong resistance to interference, even in humid environments, ensuring superior sensitivity.

Reliable Variable Frequency Speed Control Technology:

It adopts the internationally renowned Siemens variable frequency inverter, featuring high-performance vector control technology. It offers a wide speed control range, precise speed control, and exceptional overload capacity, fully meeting the requirements of quantitative batching control.

Operating Principle:

During the material conveyance by the screw conveyor, a weight sensor installed beneath it detects the material's weight and generates a voltage signal proportional to the load. Simultaneously, a speed sensor at the tail of the screw conveyor detects the speed signal of the screw conveyor's main shaft. Both signals are sent to the weighing integrator, where integration calculations yield instantaneous flow and cumulative values.